NEWS DETAILS

21

2025

-

04

New Comat’s 1150mm Cold Rolling Mill, Contracted by ZZ, Successfully Started Production

Author:

zz

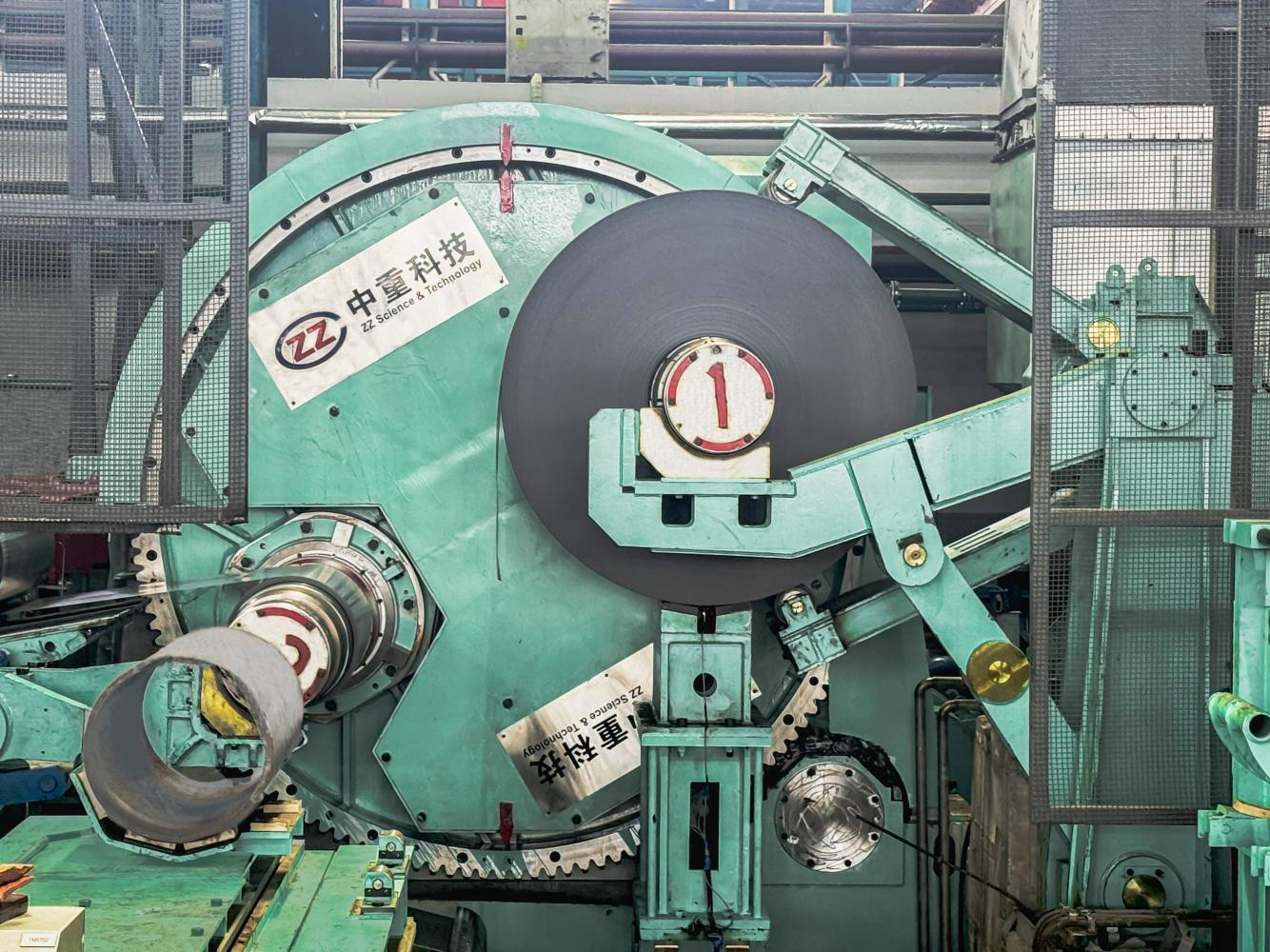

New Comat’s 1150mm Cold Rolling Mill, Contracted by ZZ, Successfully Started Production

Recently, the 1150mm cold rolling mill for Jiangsu New Comat Material Co., Ltd. (hereinafter referred to as “New Comat”), undertaken by Zhongzhong Science & Technology (Tianjin) Co., Ltd. (hereinafter referred to as “ZZ”), achieved successful commissioning as the first coil of ultra-thin precision strip smoothly coming off the line. This milestone represents another significant technological breakthrough by ZZ in high-end metallurgical equipment, while showcasing our core competencies in advanced cold rolling technology R&D and system integration.

This cold rolling mill is a full-process intelligent production line specifically designed for manufacturing high-value-added thin strips, particularly tinplate and precision thin plates. It can roll 1.8-3.0mm hot-rolled strips into 0.18-1.5mm ultra-thin finished products. The mill incorporates several core technologies to ensure superior performance:

·Precision Thickness Control (±0.005mm): Achieved through a precision rolling system featuring FM1-FM4 fully hydraulic screwdown and FM5/FM6 screwup systems, along with AGC, constant roll gap, constant rolling force and other advanced control systems.

·Intelligent Strip Profile Management: Enabled by screwdown deviation adjustment, roll bending technology, dynamic specification adjustment via intermediate roll transverse movement, and sectional cooling system, ensuring precise control throughout the entire production process.

·High-Efficiency Coiling: The Carrousel coiler allows for rapid tension establishment and extended stable rolling time, facilitating efficient and continuous strip coiling and higher yield.

Designed for high compatibility, this cold rolling mill is able to process precision thin strips of various specifications and steel grades, including Q355, Q450, 08A1, SPHC, SPHD, SPHE, ST12, ST13, ST14, MA, D, L and more. It complies with both Chinese national standards (GB/T 708-2019, GB/T 4175.1-2005, GB5213-2019) and international standards (DIN 1623-2009, EN 10130-2006, JIS G 3141-2023, and ASTM A1008/A1008M).

Jiangsu New Comat Material Co., Ltd. specializes in packaging materials, food containers, and metal products processing. Its 1150mm cold rolling mill integrates innovative technologies that drive industrial advancement, enabling the production of ultra-thin (min. 0.18mm) strips and tinplate. This establishes New Comat’s competitive advantage in high-end packaging and precision electronics. With energy-saving hydraulic system and intelligent control architecture, the energy consumption of this project is lower than the industry average by more than 15%, aligning with the principle of green and smart manufacturing. Once operating at full capacity, the mill will boost New Comat’s annual output by 30%, supporting the regional economy to seize the opportunity for high-quality development in industrial transformation.

ZZ, a global leader in high-end metallurgical equipment, has pioneered core technologies such as fully hydraulic screwdown system and digital twin control system, successfully breaking foreign monopolies in the field. The smooth commissioning of New Comat’s cold rolling mill has showcased ZZ's technical expertise and commitment to superior service. In the future, ZZ will remain dedicated to its philosophy of “Technology Empowers Industry, Smart Manufacturing Transforms the World” by strengthening strategic partnerships with domestic and international customers, further unlocking the innovation potential in metallurgical equipment, and contributing China's expertise to the transformation and upgrade of the global steel industry.

undefined