NEWS CENTER -

ZZ Science & Technology

NEWS DETAILS

24

2023

-

08

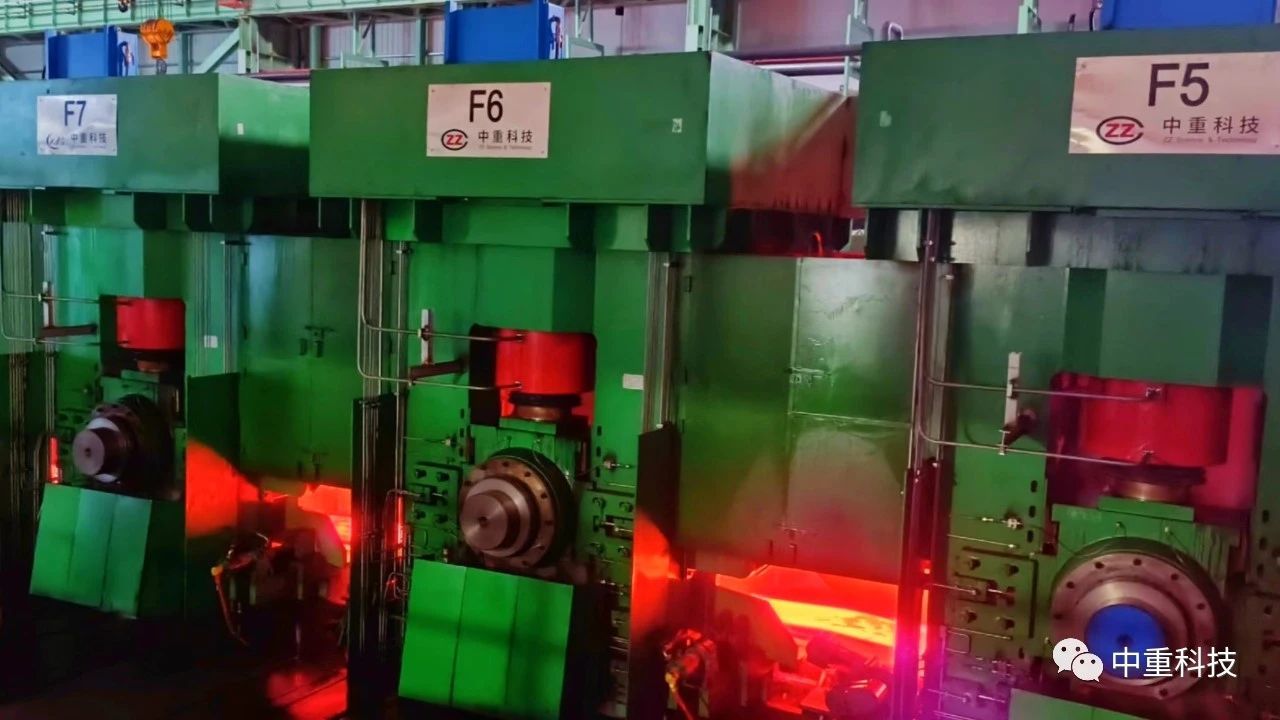

GuoTang Steel's 1100mm Full Continuous Rolling Strip Production Line Succeed in Hot Load Commissioning

Author:

zz

The thermal load test run of 1100mm fully continuous rolled strip steel production line designed and manufactured by ZZ Technology was successful, and the first qualified steel coil with a thickness of 4.0mm and a width of 850mm was successfully rolled.

At 18:18 on August 18, 2023, the thermal load test run of 1100mm fully continuous rolled strip steel production line designed and manufactured by ZZ Technology was successful, and the first qualified steel coil with a thickness of 4.0mm and a width of 850mm was successfully rolled. This production line, turnkeyed by ZZ Technology in terms of machinery, electricity, hydraumatic and dust removal, has created the fastest commissioning record of ZZ's strip steel project. On behalf of ZZ Technology, Ms. Ma Bingbing, the Chairwoman of ZZ Technology, was present at the commissioning site and expressed her congratulations to GuoTang Steel .

The 1100mm fully continuous strip production line adopts 5+8 fully continuous rolling layout, the main equipment of the production line is equipped with 2 walking beam RF, 3 vertical and 5 flat roughing and continuous rolling units, 1 flying shear, 8 four-roll finishing units, laminar flow cooling, 3 coiling mills, and palletized transportation system. The horizontal mills of the whole line are equipped with hydraulic AGC thickness automatic control function, the vertical roll mill adopts AWC width automatic control and SSC short stroke control, with L1 basic automation and L2 process automation, the finishing mills are set up with hydraulic live sleeve, and equipped with on-line control cooling process after rolling, and the rolling line is equipped with intelligent equipments, such as thickness gauge, width gauge, baling robot, and spraying number robot.

In order to enhance the competitiveness in customer's industry, save energy and reduce consumption, ZZ Technology launched full continuous rolling strip steel production process, which is a major technological innovation. It is upgraded from the traditional semi-continuous rolling process layout. The high-precision equipment, highly automated and intelligent control system provide a strong guarantee for high-quality and high-precision products. At the same time, the full continuous rolling process also has the advantages of high product precision, low energy consumption, short process, fast pace, small temperature difference between the head and tail, good plate shape, high rate of finished products, less burned, etc.. The technology has been practically applied in many production lines, and the output has been increased by 30% and the energy consumption has been reduced by 20%, which has brought great economic benefits to the customers.

The smooth commissioning of the 1100mm strip steel production line of Tangshan Guodang Steel set the record of the shortest hot load commissioning. ZZ Technology will continue to pursue excellence in technical service, and strive to make this production line a first-class benchmark project in China, creating greater benefits for customers.

undefined

Tel: +86-22-86996623 +86-18920319154

E-mail: info@tjzzjt.com

Whatsapp:+86-15102217973 +86-18526445586

Add: Gaoxin Road 65# Beichen Technology Park, Tianjin, China.

Copyright © 2023 ZZ Science & Technology All Right Reserved.

LEAVE A MESSAGE

Feedback